Europe stands at a critical juncture, facing multiple pressures, from climate change and unfair global competition to a gap in productivity growth and industrial manufacturing.

But, in the words of European Commission President Ursula von der Leyen, “Europe has what it takes to succeed in the race to the top, but we must fix our weaknesses to regain competitiveness”. Earlier this year, the European Commission presented the Competitiveness Compass that provides a much-needed clear and strategic direction to inform the European Union’s work on this front. The question is: Can the compass steer Europe towards competitiveness while decarbonising the bloc’s economy?

It certainly can.

This intention was made amply clear at the AI, Data and Robotics event organised by Adra – AI-Data-Robotics Association and the AI-on-Demand Platform, in Brussels on February 18-19.

The opening session’s focus was on “How to build a European ecosystem excellence that serves European competitiveness, now and in future?”

The opening remarks invited the audience to ruminate on how Europe can rethink its approach on competitiveness and productivity gains while responding to societal challenges, such as demography concerns in Europe, climate change, innovation gap etc.

The takeaway was that AI, Data and Robotics hold elements crucial to people’s lives and have a significant role to accelerate these societal objectives.

Adding more weight to the broader message, Cecile Huet, Head of Unit Excellence in Artificial Intelligence & Robotics from the European Commission, unequivocally said, “The future is now—but to make tangible impact, we must turn our innovations into real-time action.”

Cecile did not leave anything to imagination with a clear call-to-action for the European Research and Innovation network working in AI, Data and Robotics.

“Our role is to identify and consolidate state-of-the-art technologies, engage developers across academia, RTOs, and industry, and present clear, actionable solutions to users,” Cecile exhorted the wider community present in Brussels.

However, what Europe needs the most is a good balance between achieving competitiveness and sustainability.

Advancing green optimisation objectives across industries might hold some concrete answers. But is it a must-have or nice-to-have for the industry?

Five European Union-funded projects from the Green Deal cluster – Alchimia, Clarus, Darrow, Reclaim and Tubers – joined forces to share their knowledge at the Future-Ready On-Demand Solutions with AI, Data, and Robotics event to address how two overlapping objectives – competitiveness and sustainability – can be achieved through green optimisation.

Following an insightful exchange of knowledge, all projects were on the same page, that Green optimisation is a must-have for the industry!

RECLAIM’s prMRF, the future of decentralised material recovery

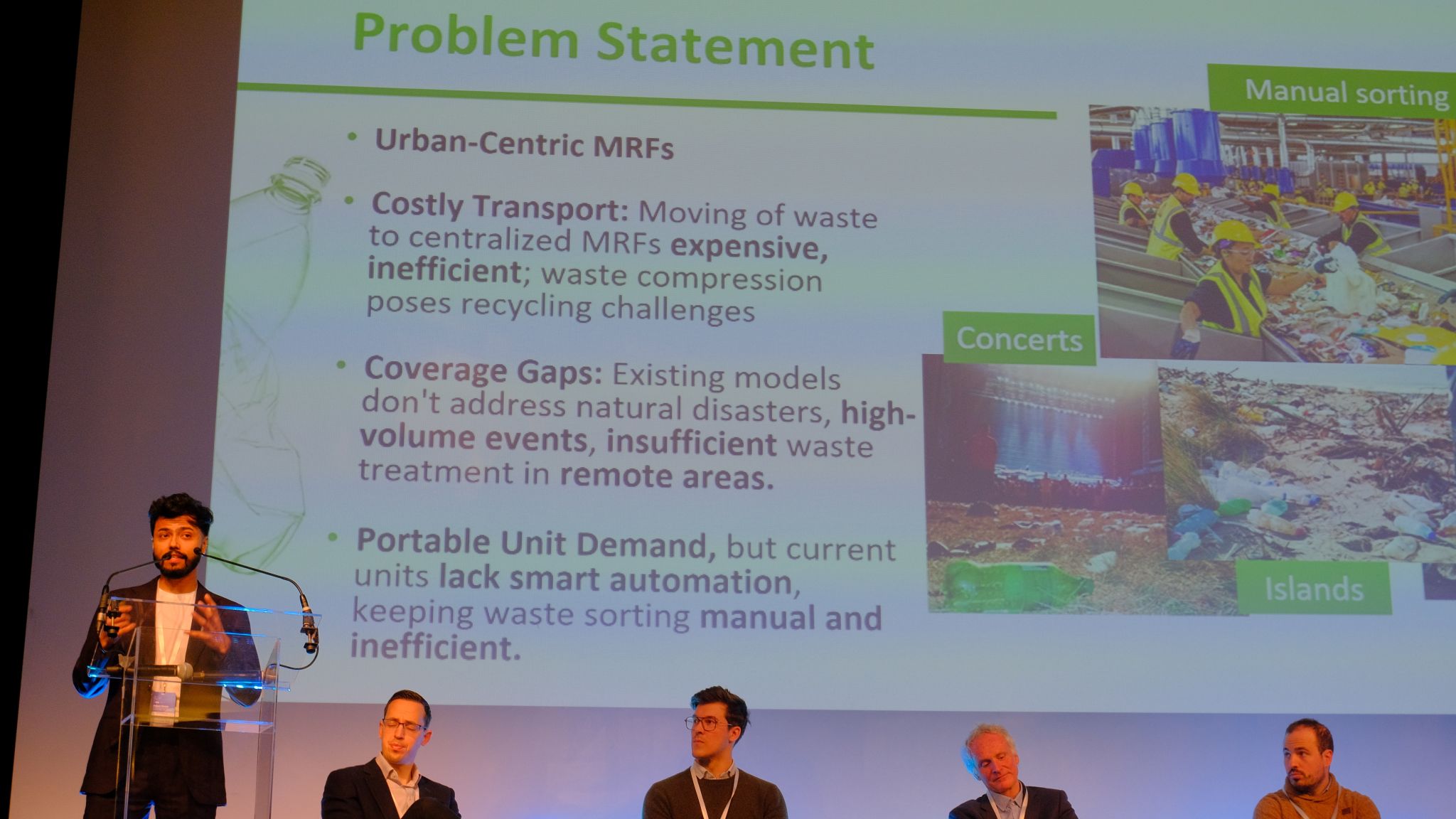

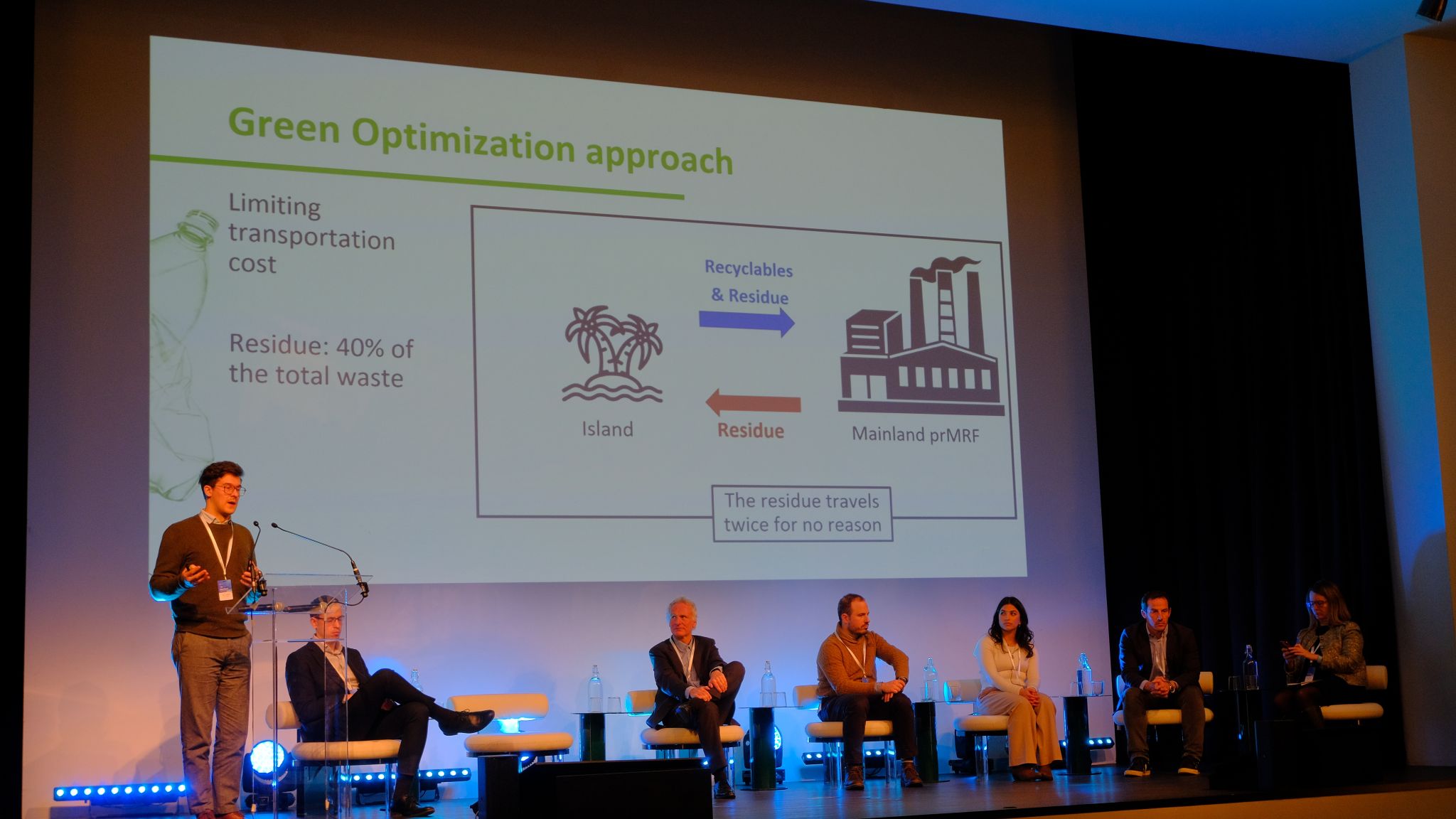

RECLAIM project, represented by Abhimanyu Chakravorty and Bart Engelen, narrated why and how our project is developing the world’s first fully automated AI-powered portable robotic material recovery facility by thinking outside of the box. Utilising the capabilities of AI, Data and Robotics, RECLAIM wants to enhance decentralised material recovery activities

Recycling operations still rely on urban-centric Material Recovery Facilities (MRFs). Over the years, while most of the MRF operations have been automated, they are still impractical for waste management in remote areas due to costly, energy-intensive waste transport. Besides, urban MRFs don’t cater to occasional high volumes of waste due to natural disasters, big-ticket concerts and events and seasonal waste generated by tourism in islands. This gap underscores the need for flexible, localised waste management solutions, which Reclaim intends to fill with its prMRF that can be deployed anywhere, even in remote areas to undertake local-scale material recovery with industrial level efficiency.

Birds of a feather… flock together: How collaborations fuel innovation

From metallurgy (ALCHIMIA Project) and food (CLARUS Project) to solid waste material recovery (RECLAIM), to robotic solutions for drinking water networks (TUBERS Project), and wastewater treatment (DARROW Project), the Birds of a Feather workshop is united under one goal: to advance multi-sectorial approach to green optimisation using AI, Data and Robotics.

Besides Reclaim, these were the other projects highlighting cross-industry advancements:

🔧ALCHIMIA Project – AI for energy-efficient metalworking

DARROW Project: Harnessing AI for smarter wastewater treatment

🥗 CLARUS Project – Machine learning for sustainable food production

🔍 TUBERS Project – Autonomous robotics for pipeline inspection

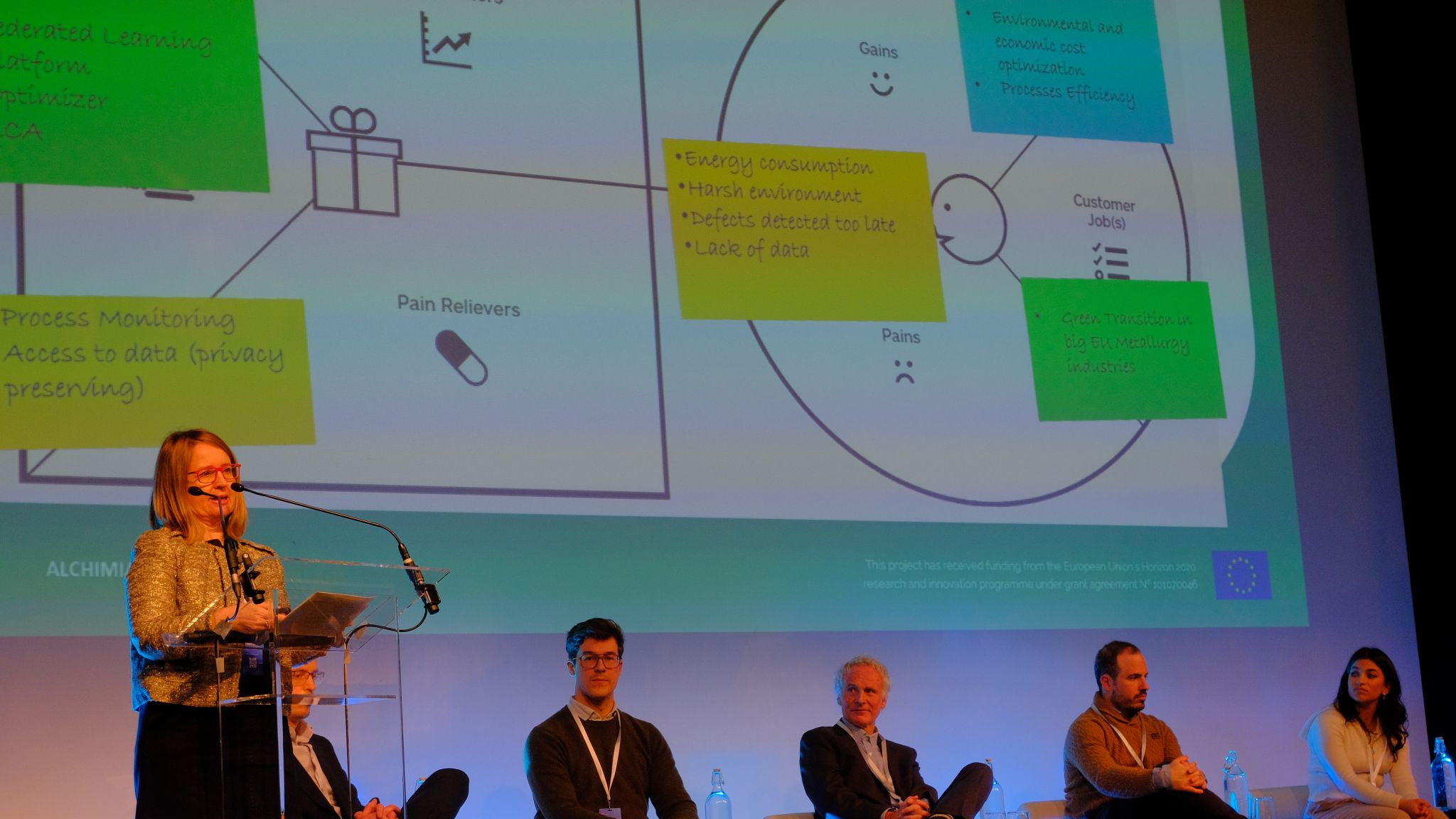

ALCHIMIA Project: AI-driven efficiency in metallurgy

Europe is on a mission to become the first climate-neutral continent, and industries have a big role to play. But for energy-intensive sectors like metallurgy, the challenge is real—how do you stay profitable while going green?

That’s where ALCHIMIA Project comes in.

This EU-funded project is helping metalworking industries transition to more efficient, competitive, and sustainable production without compromising quality.

🔹 Cutting energy use, emissions, and waste in steel-making

🔹 Finding the optimal mix for greener, high-quality production

🔹 Supporting the shift toward a climate-neutral and circular economy

Visit their website.

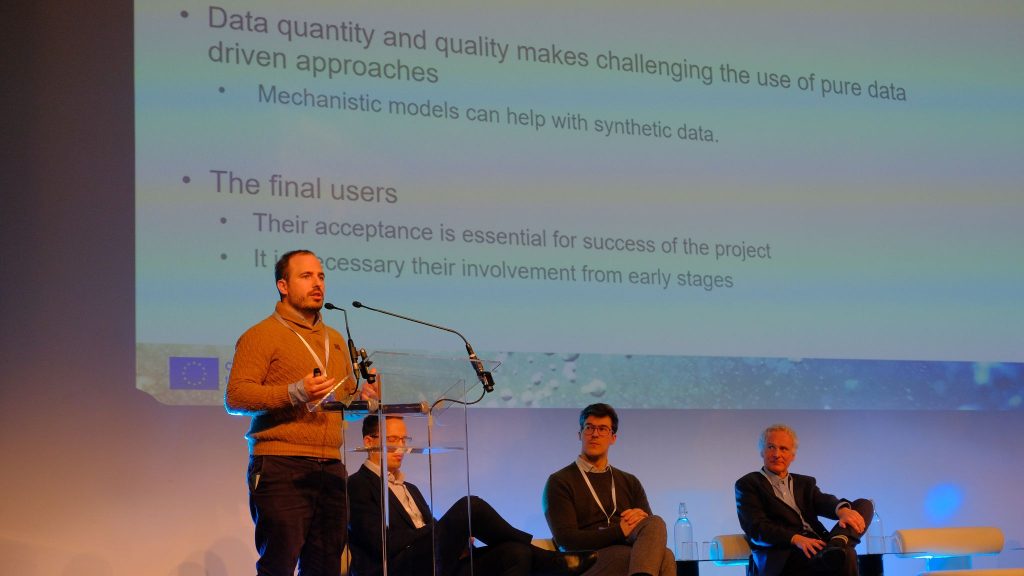

CLARUS: AI and Data for sustainable food industry

CLARUS Project‘s Ludovica Miele and Francisco Fraile, PhD presented how the project harnesses AI and Data tech to drive sustainability in the food industry, which is one of the biggest consumers of natural resources.

By leveraging AI, CLARUS not only aims to enhance production efficiency but also aligns with the Green Deal’s sustainability goals. Visit their website.

The workshop was a perfect synthesis of collaboration, engagement and action, thanks to ALCHIMIA Project for leading the coordination of the workshop and AI-on-Demand Platform and Adra – AI-Data-Robotics-Association for providing all the EU projects a platform to showcase our respective innovations in AI, Data and #Robotics.

Darrow: Harnessing AI for smarter wastewater treatment

Wastewater is a valuable resource!

Enhancing its recovery can:

💡 Save energy⚡

🌍 Cut greenhouse gas emissions 🌱

♻️ Boost the circular economy 🔄

🚯 Minimize waste 🏭

DARROW Project is doing just that, by making wastewater treatment more sustainable and efficient using a data-driven AI solution. Visit their website.

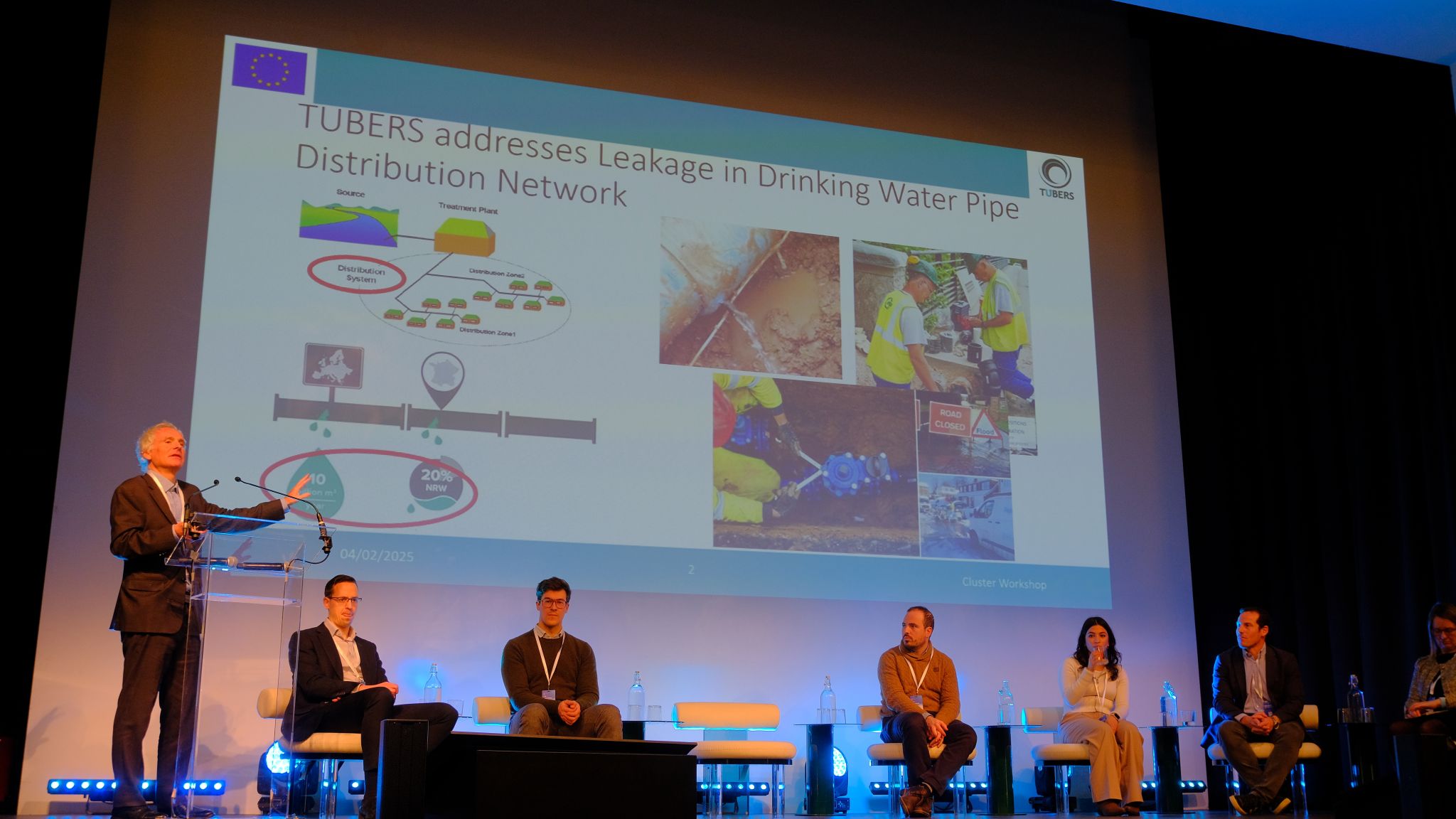

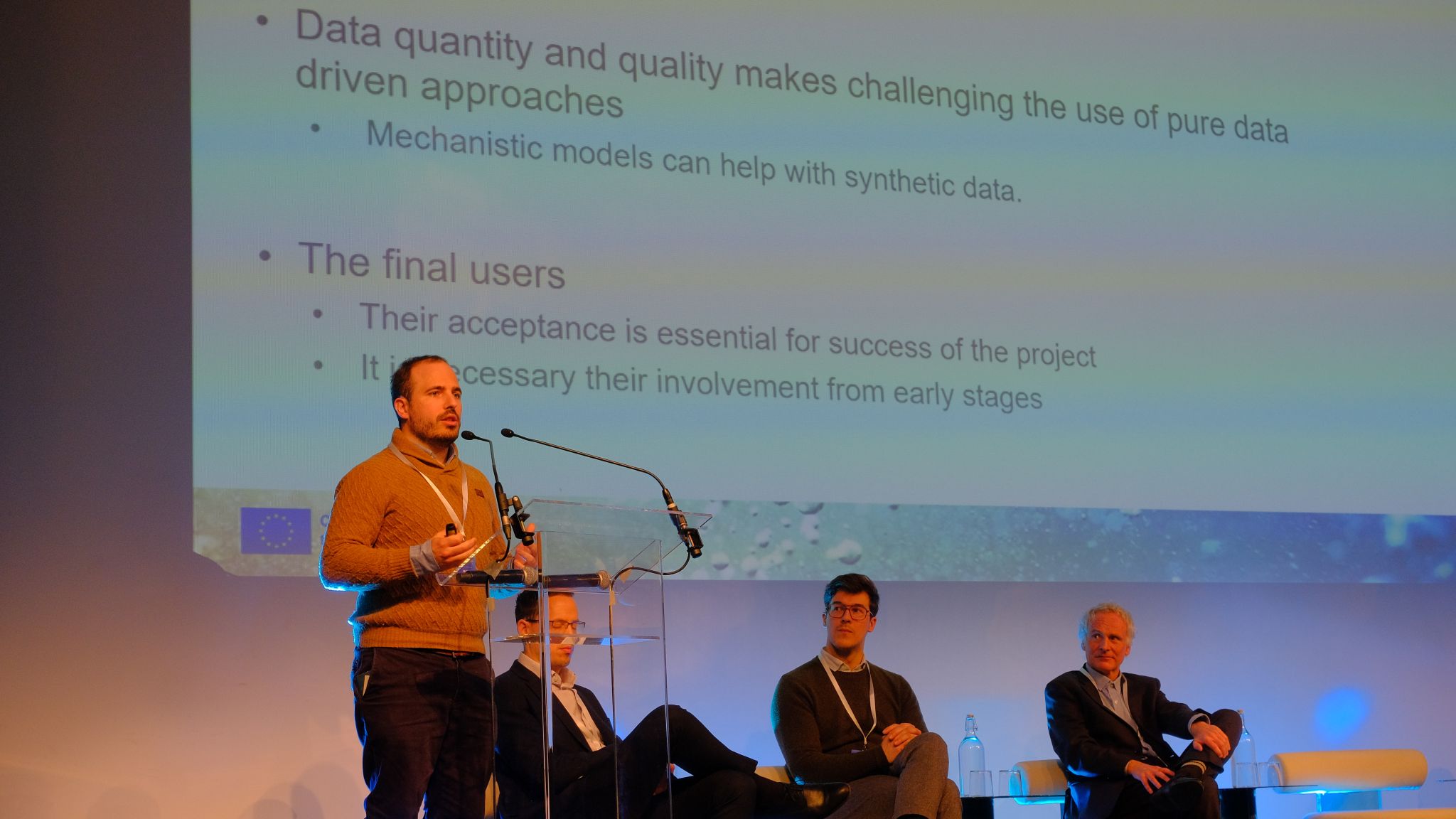

TUBERS Project: A resilient shield for water systems

🚰 The challenge: How can we make Europe’s water distribution system more resilient?

Europe’s water infrastructure is under pressure from leaks, contamination, and rising energy use. Ageing pipes and construction flaws waste water, drive up costs, and strain the environment. Without smart monitoring and intervention, sustainability is at risk.

💡 The Solution: TUBERS Project – A resilient shield for water systems

TUBERS is developing a next-generation ecosystem of:

🔹 Robotic tools for high-accuracy pipe inspections and repairs

🔹 Digital systems for real-time monitoring and prevention

🔹 Eco-friendly solutions to support a Circular Economy

The Birds of a Feather workshop was a perfect synthesis of collaboration, engagement and action, thanks to ALCHIMIA Project for leading the coordination of the workshop and AI-on-Demand Platform and Adra – AI-Data-Robotics-Association for providing all the EU projects a platform to showcase our respective innovations in AI, Data and Robotics.

And yes, Green Optimisation is a Must-Have for the industry, as all the projects collectively believe that we can achieve competitiveness and sustainability supported by AI, Data and Robotics.