We are back from Kefalonia island in Greece, with sun in our soul and sand in our hair (and feet). And lots of trash talk, especially as the consortium was there to see for the first time the portable robotic Material Recovery Facility (prMRF) in action.

We did a LIVE LinkedIn video from the deployment site. Have you watched it yet? If not, view the video here.

The visit to Kefalonia had dual objectives, for a consortium meeting to review project progress before project closure in August this year and see the prMRF work with waste on the island in real, challenging conditions.

In that sense, the Kefalonia deployment is a major milestone for RECLAIM project. This is the first time since project inception in 2022 that our solution has been deployed in the target island of Kefalonia for testing and evaluation. So far tests have been conducted only under semi-real conditions, meaning not with real waste streams. But in the weeks to come, the prMRF will be operating two days in a week daily and challenging tests and evaluations will be conducted on the fly.

Kefalonia has been chosen as the target island for intervention due to several reasons.

During peak tourist seasons, typically between May and September, the average monthly waste generation increases by at least 60% compared to the rest of the year, driven by seasonal surges in tourist population. Inadequate infrastructure, limited public awareness of effective waste management practices and resource constraints within waste management organisations contribute to low recycling rates, adding pressure on an overburdened system.

Kefalonia’s waste management woes are unique, but they reflect broader issues faced by many remote areas in Europe with limited waste management infrastructure. That’s why our prMRF aims to provide smarter, efficient and flexible robotic Material Recovery Facility (prMRF) to address the islands’s waste management challenges.

Three years into our project, and we’ve got a lot to show and tell. What started as a bold vision to bring decentralised, high-tech waste management to remote regions has now become a working reality — and the journey has been challenging but very fulfilling, and more work lies ahead.

Our Kefalonia press release can fill you in on why we are deploying the prMRF in Kefalonia and its capabilities. Download here>

Updates from Kefalonia visit: View the images below!

In our consortium meeting, the project coordinator Michalis Maniadakis from FORTH-ICS emphasised that significantly much more difficult operating conditions will be considered for the prMRF than right now.

But for now, what is a crucial milestone for RECLAIM is that the prMRF has already been tested and demonstrated at Technological Readiness Level 7 (TRL7) in an operational environment.

This is considered the Minimum Viable Product (MVP) of the project and the main result.

The prMRF has already been demonstrated to the consortium partners, and now selected audiences, such as the scientific community, stakeholders interested in waste management and potential investors will be invited to see the demo of the solution for commercial exploitation.

Additionally, the exploitation and potential commercialisation of other project assets, such as Robotic Recycling Workers (RoReWos), AI-Identification, Localisation and Categorisation module AI-ILC), and Recycling Data Game (RDG) is now being actively pursued.

A Landmark for Kefalonia: Smarter Waste Management at Pallosti

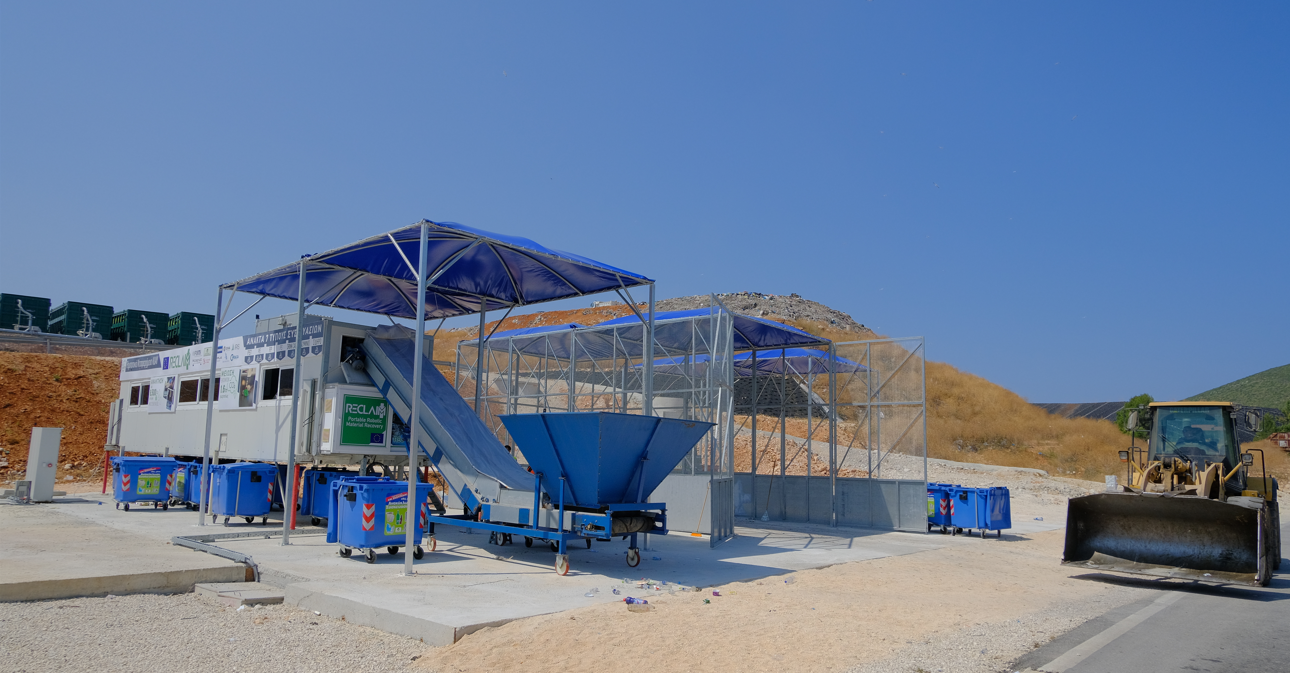

If you’ve seen the photos, you’ll have spotted Kefalonia’s only landfill located in Pallosti. Right beside it now stands our prMRF, working tirelessly to help keep valuable materials out of the landfill and give them a second life.

Kefalonia’s citizens play a crucial role in this transformation. By separating Plastic, Metal, and Drinking Cartons (PMD) and depositing them into Blue Bins with Red Lids and Red Stickers, residents help ensure clean recyclables enter the recovery stream.

This simple act:

👉 Keeps waste from ending up in landfills or being incinerated — protecting our environment.

👉 Enables the municipality to collect quality recyclables.

👉 Allows the prMRF to recover valuable materials efficiently.

It’s a win for individuals, the community, and the planet.

Compact, Clean Tech: The Power of the prMRF

One of the most impressive aspects of the RECLAIM prMRF is how cutting-edge technology fits inside a standard shipping container.

The prMRF uses:

✅ AI and computational vision to identify and classify materials.

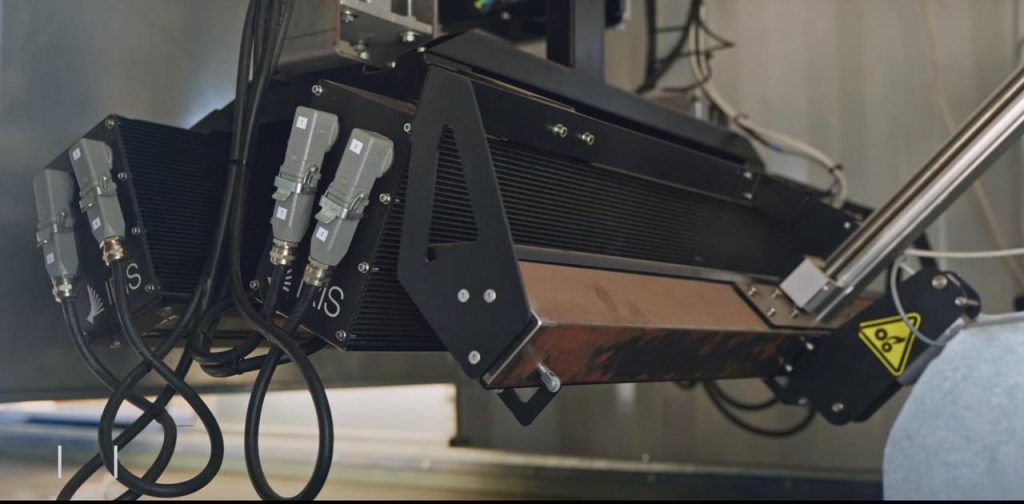

✅ Hyperspectral imaging for precise material recognition.

✅ Robotic sorting system to recover valuable waste with minimal human intervention — keeping people out of unhealthy working conditions.

✅ Live web-monitoring interface for remote operations from anywhere

And in keeping with our commitment to sustainability, part of the prMRF’s energy needs — especially in remote regions of Greece — will be met by renewable sources, including solar panels that produce energy from sunrise to sunset. The facility aims to operate for over 8 hours daily, maximising material recovery and contributing to the circular economy.

The unique capabilities of RECLAIM’s prMRF include:

- Quick deployment: Container is fully operational in less than 2 days.

- Adaptability: Adaptable digital systems and modular robotic teams can be

reconfigured—often within 30 minutes—to handle various waste types based on local

conditions. - Flexible operation: prMRF accommodates a double-shift schedule during busy tourist

months and a single-shift schedule during off-peak seasons, ensuring efficient year

round operation. - High performance: Capable of operating non-stop, double shift, daily the prMRF

accomplishes high recovery rates. The system’s AI is regularly retrained to improve

sorting accuracy and reduce waste contamination. - Remote monitoring: A web-based interface allows production managers to remotely

monitor operations and access real-time data on robotic processes and hyperspectral

imaging, enabling iterative improvements even under challenging conditions. - Enhanced sorting capabilities: Achieves an average of 120 picks per minute, but can

easily be upgraded with additional robotic sorters to reach even higher productivity. - Sorts 7 different material types:

– PET (Polyethylene Terephthalate) – plastic bottles

– HDPE (High-Density Polyethylene) – detergent bottles, milk jugs

– Aluminium – cans and food packaging

– PAP – drinking cartons

– PP (Polypropylene) – food containers, bottle caps

– PS (Polystyrene) – foam packaging, disposable cups

– LDPE (Low-Density Polyethylene) – plastic bags, wraps

June pRMF demo to consortium: From Theory to Practice

Our recent live demo in Kefalonia marked the culmination of three years of hard work. What once existed on paper is now a fully operational, AI-powered, portable solution for waste recovery — a first of its kind. The LIVE demonstration event showcased the potential of real-time, decentralised waste management for remote areas, such as islands, and was a proud moment for the entire RECLAIM team.

What work has been done so far

For deployment, the transport and installation of the prmRF in the designated position has been achieved as well as the construction of shelter for the installed equipment (prMRF, feeder, and baler) in the operating area.

The trial operation has begun, and the installation and operational timeline for the prMRF has been finalized.

What’s next for RECLAIM?

While the project formally wraps up in August, this is far from the end. The focus now shifts to commercialising the prMRF — bringing its benefits to more regions and advancing the circular economy, particularly for remote and underserved areas.

What remains to be done is the testing and evaluation of the prMRF in Kefalonia and operations monitoring and productivity measurements will be conducted by FORTH, ION, Robenso and HERRCO.

It is likely that we will conduct another round of demonstration for Local and Regional Authorities (LRAs) in Kefalonia again. You will hear from us soon!