RECLAIM has developed a fully operational portable robotic Material Recover Facility (prMRF), ready for optimization and real-world deployment. This portable, containerized robotic facility, integrates advanced robotics, computer-vision and hyperspectral imaging technologies to achieve small-scale waste processing for material recovery. Its operation is supported by a web-based interface allowing the production manager to monitor the performance of the technologies installed in the prMRF. The interface allows the production manager to access real-time information on robotic operations and hyperspectral imaging data with just a few clicks on a mobile phone or tablet.

Monitoring takes place in real time with the assistance of two security cameras, which are located in the middle and at the end of the container. The production manager can observe in real time the performance of robots and the success rates of their actions, having the chance to identify in time possible problems due to unforeseen events. Through the interface, he can remotely control the robots and make operational adjustments to maximize prMRF productivity and ensure high material recovery rates.

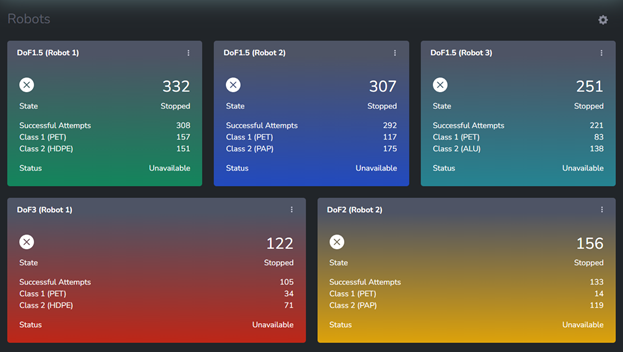

When the person in charge accesses the interface, the first thing appearing is a dashboard with five boxes of different colours (see Figure 1), each representing one of the robots operating inside the prMRF. The first three boxes correspond to linear robots with 1.5 degrees of freedom (DoF), while the two below are the 3.0 DoF robot and the 2.5 DoF robot, respectively. All robots are equipped with a vacuum mechanism and a suction cup for picking and sorting waste. Each robot is responsible for recovering waste from two different material types. In this section, the project manager sees the two recyclable material categories treated by each robot, the number of the recovered items for each category and also the robot’s current status. For example, the first robot (DoF1.5) is assigned to pick PET and HDPE recyclables. Moreover, by using this interface it is possible to modify the types of recyclables recovered by each robot while the overall system is still in operation, offering flexibility and adaptability for optimized waste recovery.

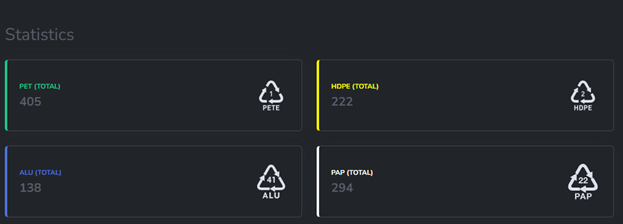

On the same page, there is also a statistics section providing valuable information such as the amount of waste processed for each recyclable material type recovered by the prMRF, in particular PET, HDPE, ALU, PAP, PP, PS, LDPE and OTHERS. This information allows the production manager to easily track the number of items grasped by the robotic grippers, for each material type. Depending on the productivity of the robots and the composition of the incoming material, the operator may redistribute the robots’ roles in order to give more emphasis to the recovery of certain materials.

Moreover, using the visual interface, the production manager can call each of the robots for periodic maintenance and suction cup cleaning, so as to keep the robot’s efficiency at a high level.

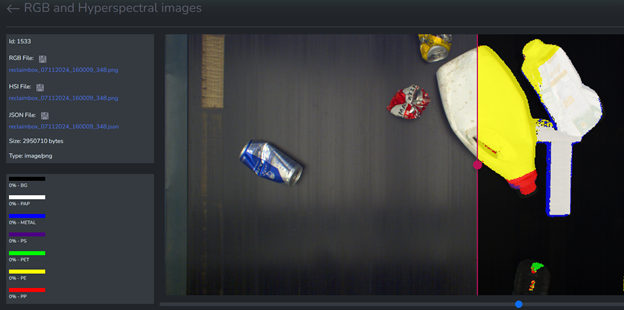

The RGB and Hyperspectral images section allows the operator to inspect the joined performance of waste identification in the visible and infrared spectrum along with the corresponding material categorization predictions. This data can be saved for offline assessment of the AI models used in waste categorization or downloaded for re-training in order to incrementally enhance model performance.

As summarized above, a key component of the prMRF innovation is an intuitive interface for the real-time monitoring of the overall system operation that provides the production manager with unprecedented visibility into the waste recovery process. Its user-friendly, intuitive layout, combined with compatibility across mobile devices, makes it convenient to use from anywhere. The interface enhances the effectiveness of waste management, as the real-time monitoring of the waste processing enables quick decision-making and proactive maintenance, while also providing data-driven insights to optimize material recovery strategies in the long-term.

Overall, the interface summarized above is more than just a tool for the prMRF, as together they constitute a powerful, agile and transformative solution for waste management. By combining robotics and advanced imaging technologies with structured real-time performance monitoring, the production manager has the power to make informed decisions, shifting prMRF performance to match the requirements of a particular waste treatment sites, effectively contributing to a cleaner, more sustainable world.