The Munich Plenary, organised by Axia Innovation, was the fifth meeting in the last two years of the project, and much has been deliberated upon and action steps identified for the next few months until project completion.

Key Messages

1. prMRF to be deployed in Kefalonia Island in March

2. prMRF running long tests daily without human intervention

3. IRIS’ new waste categorisation model improves material accuracy

4. Multi-Robot Grasping Approach Unique in RECLAIM, explains KU Leuven

5. Recycling Data Game gets an update: new “Drop” mini game

6. HERRCO finalising prMRF operational timeplan

7. RECLAIM sealed collaboration opportunities with EU projects at Ecomondo

8. prMRF to be showcased at VerdeTec, 2025 in Greece

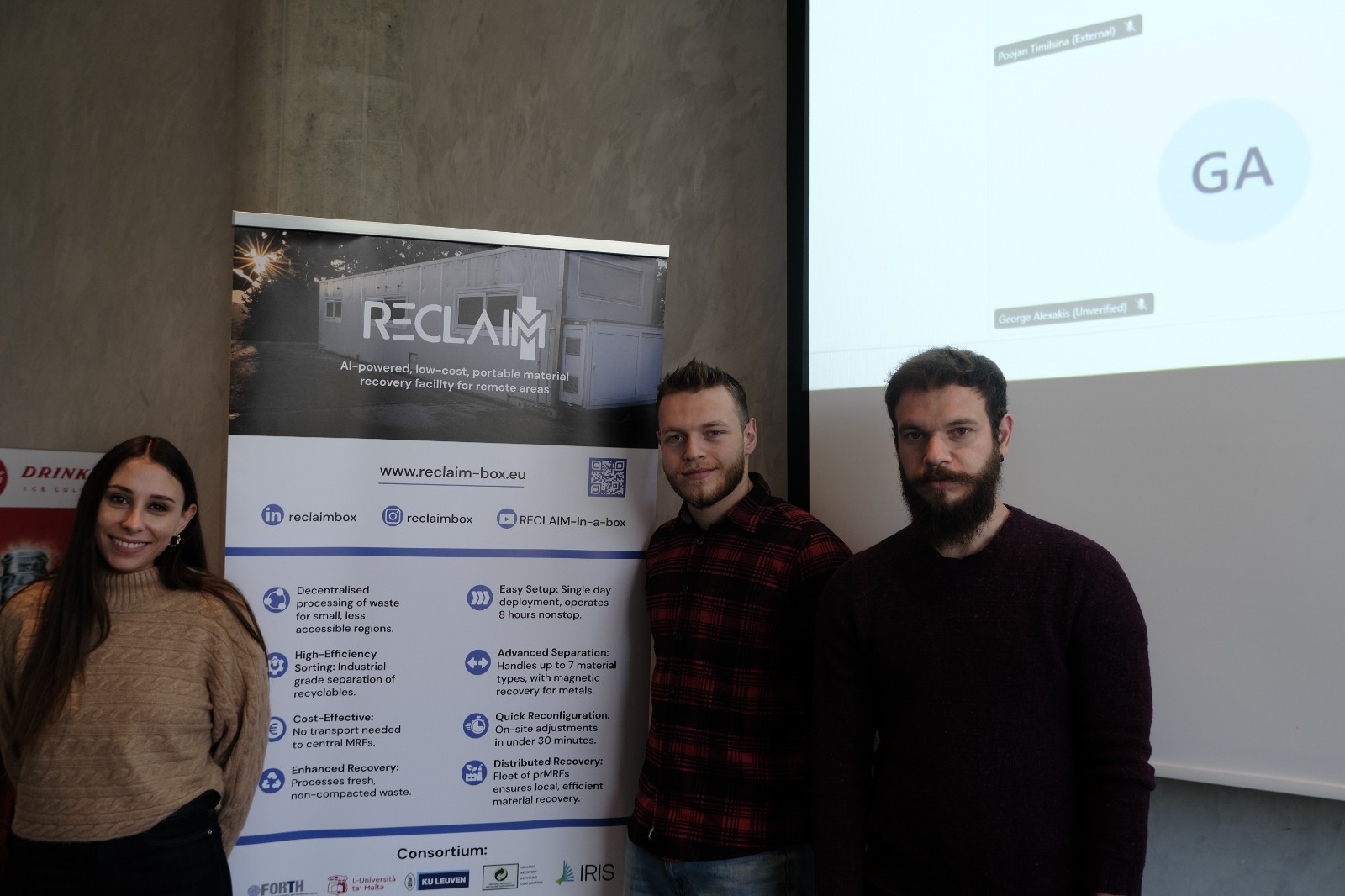

With a few months remaining until project completion, the RECLAIM project’s fifth plenary meeting took place in Munich earlier this month with the intention to review actions undertaken, resolve challenges, enhance cooperation among partners, and speed-up progress to implement the portable robotic material recovery facility in the island of Kefalonia.

The plenary meeting, organised and managed by consortium partner Axia Innovation, took place a few months after a successful General Assembly (GA) hosted by KU Leuven at their Department of Mechanical Engineering campus.

The Munich meeting started on a positive note with the project coordinator Michalis Maniadakis announcing the main takeaway message.

The prMRF will now be deployed in Kefalonia Island from March onwards to demonstrate its real-world capability in material recovery of post-consumer solid waste, added Maniadakis.

This will be the first time that the prMRF will be displayed to the public and they can participate and give their feedback to us on our project idea as well as the objective that it intends to achieve, which is decentralised, industrial-level efficiency in material recovery.

Multi-robot grasp planning approach in RECLAIM is unique

KU Leuven is also working on the multi-robot grasp planning approach to increase value recovery. For example, in the project, they are combining various gripping technologies to enable multiple robots to work in a complementary fashion. “For this, KU Leuven developed digital twins and novel scheduling algorithms to maximise value recovery while considering the distinct efficiencies of different grippers for the handling of complex and variable waste streams,” explained Jef Peeters.

Similarly, FORTH also has work cut out for them to test the new multi-cup gripper equipped with a vision-based system that selects the most suitable suction cup. What the system does is identify the largest flat surface on an object to determine the optimal gripping points, ensuring the largest possible suction cup is used for a secure grip. While testing has so far been limited to the lab, prMRF testing is scheduled for mid-December.

New Images of the prMRF

Material identification accuracy further improved

In Work Package 3 (Recyclable Waste Detection and Categorisation), IRIS made progress too. They presented results from their new waste categorisation model combining the Low-Density Polyethylene (LDPE) and High-Density Polyethylene (HDPE) categories into a single PE category. In doing so, material identification accuracy improved.

Within WP3, FORTH works on waste monitoring in the visible and infrared spectrum. In this, FORTH developed a method for combining the results of processing the Hyperspectral Imaging (HSI) and RGB images, to create a single unified output related to the size of the object and its material type, which are then used by the prMRF robots for the physical sorting of waste.

To explain the impact of this process, of combining results obtained from HSI and RGB images, on improving imaging accuracy, Maniadakis said, “The process combines RGB imaging to detect and segment objects (creating “masks” for specific regions) with Hyperspectral Imaging (HSI) to analyse the material composition of those regions. RGB identifies object shapes, and HSI determines the dominant material by analysing its spectral signature, enabling accurate waste material identification for recycling.”

Recycling Data Game gets an update: new “Drop” mini game

The Recycling Data Game (RDG) also received a few updates.

Antonios Liapis from the University of Malta’s Institute of Digital Games said they have created a mini game called “Drop”, which is now ready for preliminary tests. Explaining the new addition, Liapis, who is developing the RDG in the consortium in collaboration with other partners, said, “This feature has arcade-style controls where users sort items into bins as they move along a conveyor belt. Players are tested both on how quickly they can complete the challenge and how accurate their picks are (if they drop PET bottles to the PET bin, for example). This version is faster-paced and more entertaining compared to previous versions.”

Soon, the game can be downloaded from the Google Play Store and playable on all Android devices!

HERRCO finalising operational time plan of prMRF

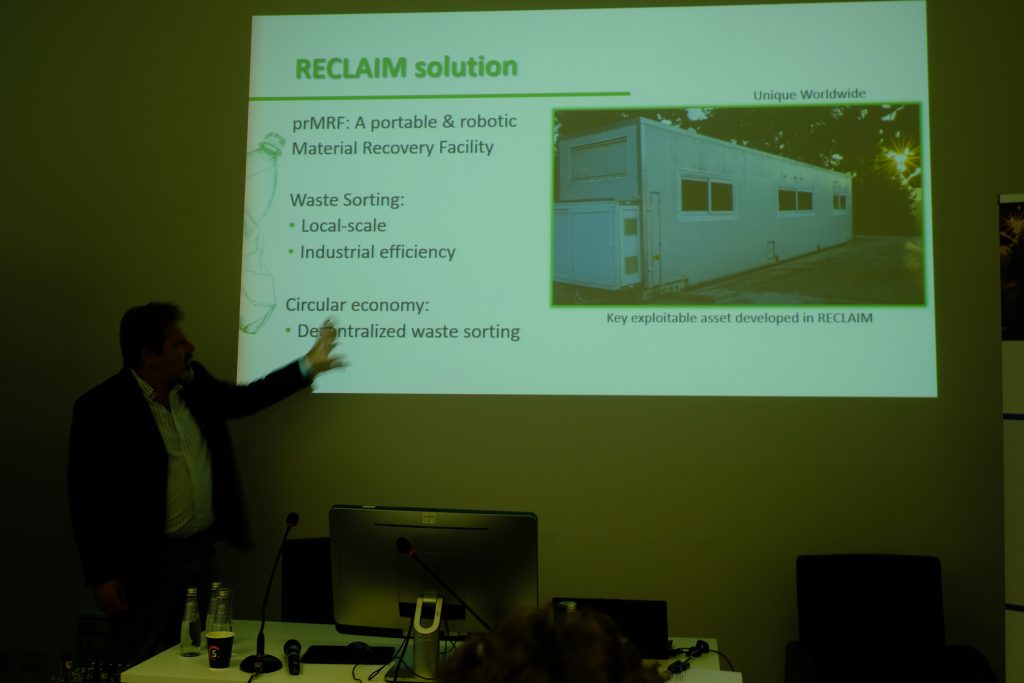

In the end, the innovations and technologies developed in the project will be implemented inside the prMRF container, which is critical to the project’s success.

Here, Hellenic Recovery and Recycling Corporation (HERRCO), the RECLAIM implementation partner, steps in with a major contribution.

Currently, HERRCO is looking into the installation plan for the prMRF in the waste treatment facility of the Kefalonia Island, including the installation of prMRF in a designated position and finalisation of installation and operational time plan of the prMRF. This is to ensure that the prMRF can continue to work at the designated site beyond the project timeline.

Vasilis Makridis, COO of HERRCO, underscored the importance of their role in the project, given that ultimately HERRCO will supervise the prMRF operational phase but also evaluate the prMRF’s efficiency, such as productivity and recovery performance, and its future deployments.

In addition to this, HERRCO is also responsible for the equipment of mechanical sorting, for example, vibrating inclined screen, sorting/return belts, magnet, special recovery/return structures, hydraulic lifting legs, etc.) and the inclined feeder hopper.

AXIA engages local waste company in Munich for guidance on prMRF operations

Much has been said about the technologies that will change the waste management and material recovery game with the introduction of the prMRF in the market, especially in Greek Islands to start with. However, equally crucial is the exploitation and business innovation aspects that seek to maximise project impact. Axia Innovation, the consortium partner responsible for project impact maximisation, conducted another thorough analysis of the key exploitable results (KERs), with particular attention to co-developed outcomes that involve shared ownership among partners.

The results of the exploitation and intellectual property rights (IPR) questionnaire were presented and discussed, leading to the development of KER characterisation tables. These tables will serve as the basis for crafting detailed exploitation roadmaps tailored to the partners’ intended use—whether scientific or market-oriented.

Finally, the updates on the business plan of the prMRF were reviewed along with the tasks required to finalize the business plans of the project´s three main outputs: a) the prMRF, b) the AI-ILC module and c) the RoReWos. The goal is to complete comprehensive business plans for these key outcomes by the end of the project.

In addition, RECLAIM also connected with the local waste disposal company in Munich engaging them as a key stakeholder in the project. Their involvement provides valuable feedback and guidance for the operation of the pilot material recovery facility (prMRF).

ECOMONDO exhibition in Rimini, Italy

Finally, RECLAIM, with consortium partner ISWA’s support, participated at Ecomondo exhibition in Rimini, Italy between November 5-8 to collaborate with like-minded EU-funded projects in order to broaden dissemination efforts. ISWA, a communication and dissemination partner for the EU-funded Reclaim and Wood2Wood projects, organised and managed the collaborative efforts at the exhibition through a workshop and a special booth day.

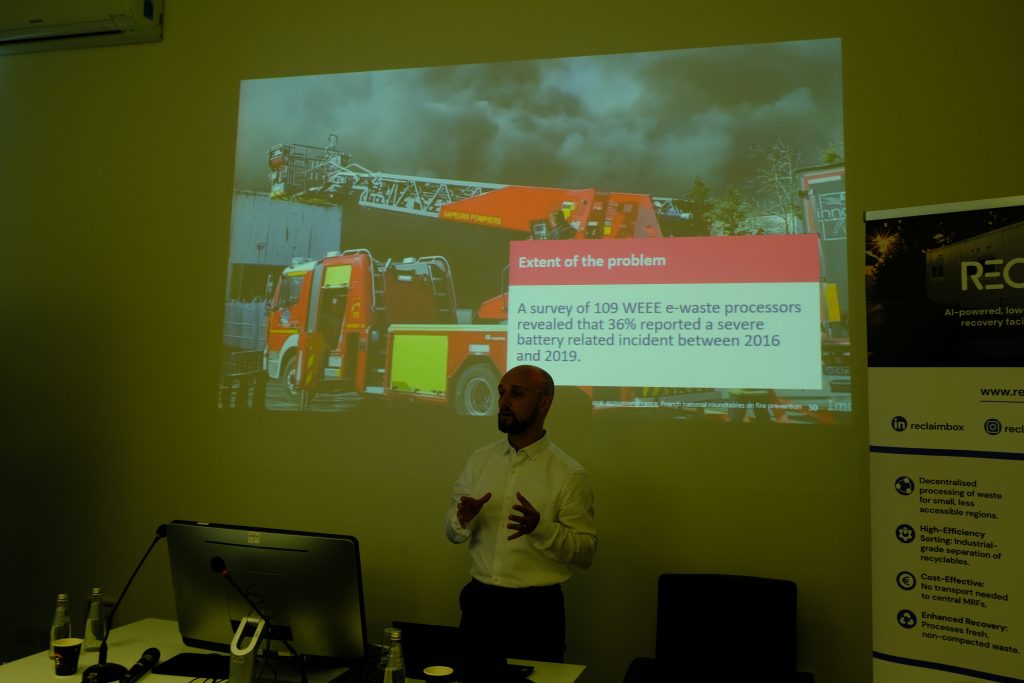

In the workshop titled “From Waste to Resource: Innovative Approaches to Material Recovery and Sustainable Waste Management”, four projects, namely Reclaim, Grinner, Wood2Wood and EcoReFibre brainstormed on effective, efficient and sustainable pathways to advance circularity imperatives of the European Union (EU).

The four projects presented their technological innovations in material recovery, using Artificial Intelligence, Robotics and Advanced Imaging, across different waste streams, such as municipal solid waste, Waste from Electrical and Electronic Equipment (WEEE) and wood waste from construction and demolition (C&D), and furniture waste.

Read more here

Watch the video of our project coordinator speak about the next steps in RECLAIM with EU-funded projects

What’s the way ahead for RECLAIM from here?

Looking into the future, the project intends to showcase the prMRF at VerdeTec exhibition in Greece next year February 2025, followed by the deployment in Kefalonia Island for a public display of the material recovery operations. Extensive testing has been conducted in semi-real conditions to ensure the prMRF is up to the task.

But more tests are necessary in Kefalonia. Meanwhile, the project is contemplating to include a Web flight deck for monitoring and controlling prMRF operation. With this web-app, authorised users can observe real-time statistics regarding the performance of all the components installed inside the prMRF and parameterise their functionality.

See you at Verde Tec!