Information on common recyclable materials and the current situation in the solid waste management industry.

The process of recycling has played an important role in the human economic activities for many years. Its history begins in the Bronze Age where people melted their used metallic objects so that new products could be produced from them. However, although humans have been recycling their remnants since prehistoric times, the systematic form of recycling we all know today emerged in the early 20th century. In recent years, due to population growth, urbanization and economic development, waste production has really increased. The amount of global solid waste production is estimated to be around 1,3 billion tons per year while it is expected to reach 2,2 billion tons by 2025 and 3,4 by 2050. For environmental, economic and ethical reasons, such high levels of waste production have caused significant growth in the recycling industry.

Recycling is defined in technical terms as the process through which packaging materials (glass, paper, plastic, aluminum, tin and wood) are reused and reintroduced into the production cycle. However, for this to happen, the recovery of recyclable materials from the total mass of waste must be preceded, as well as their categorization and sorting into different streams depending on their material type. The term “recycling” includes the collection, transport, storage, recovery and processing recyclable objects with the aim to develop the raw material for the development of new products. The recycling process is an important way to reduce the environmental footprint of the ever-increasing demand for goods packaging that is no longer sustainable.

One of the most common recyclable materials is plastic. We find plastics very often in our daily life in items such as packaging, clothing, sports equipment, medical devices, electronics, toys, furniture and many others. They are cheap, light, ductile and durable materials and thus can be easily used in a wide variety of products with a wide range of applications. As a result, the volume of the plastics being used is huge and this is the main problem with the use of plastics because their decomposition happens at a very slow rate. The recycling of plastic packages is an important way of saving resources, since the total energy needed to recycle e.g. a plastic bottle, is insignificantly lower compared to the energy consumed to manufacture it.

Another common recyclable material is paper. The production of paper has significant effects on the environment, the most important being logging. Paper recycling can stop the degradation of the forest ecosystem and contribute to addressing atmospheric pollution and preserving natural resources. Indicatively, it is stated that recycling one ton of paper saves 17 trees and half of the energy and water consumption used during its initial production. Because many types of paper with different quality are produced, sorting it is difficult and material recovery facilities separate paper into three categories: cardboard (paper boxes, packaging), liquid paper (paper packages containing liquids such as milk, juices) and printed paper (magazines, newspapers, documents).

Glass is another recyclable material which does not decompose. Further to being reusable for the packaging of a product, it can be recycled over and over again to produce same quality glass packages. The recycling of glass for the production of raw materials contributes significantly to saving energy since up to 90% of spent resources are saved. Recycled glass can have different applications such as kitchen tiles, countertops or wall insulation. Using shards to produce glass objects from recycled glass saves money and energy as shards cost less compared to raw materials and melts at a lower temperature.

A fourth very common recyclable material is aluminum. The recycling of aluminum cans that are commonly used in the packaging of soft drinks and other drinks can drastically reduce the volume of waste while saving very high percentages of energy (95%) required for their initial production. It is remarkable that aluminum recycling needs only 5% of the energy required for the primary production of the same amount.

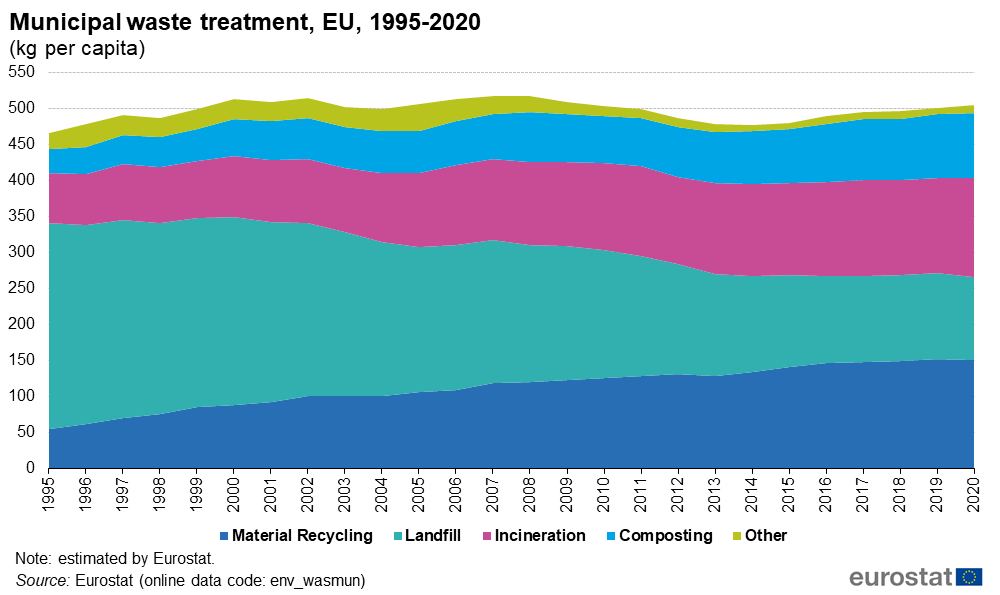

As shown in the diagram below, in previous decades recycling was not sufficiently adopted for solid waste management and a very large percentage of waste ended up in landfills. A key factor that contributed to this was the lack of information among citizens who were either indifferent to the issue of recycling or unaware of which exactly recyclable materials should be recycled. Despite that, the recycling rate of municipal solid waste in EU increased significantly from 10% in 1995 to 35% in 2020. The technological development that has taken place the last few years in the collection, separation and recovery systems of recyclable plastics have created new possibilities and market opportunities, what is today known as the “circular economy”.

In this framework, the RECLAIM project will develop a portable, robotic MRF (prMRF) tailored to small-scale material recovery. The proposal exploits well-tested technology in robotics, AI and data analytics which is improved to facilitate distributed material recovery. RECLAIM adopts a modular multi-robot/multi-gripper approach for material recovery, based on low cost Robotic Recycling Workers (RoReWos). An AI module combines imaging in the visual and infrared domain to identify, localize and categorize recyclables. RECLAIM developments will be implemented and repeatedly assessed in demanding, real material recovery tasks. Three different scenarios will attest its effectiveness and applicability in a broad range of locations that face material recovery challenges. This will pave the way for the prMRF market uptake and provide a major boost in making Europe zero polluting, climate-neutral, sustainable and globally competitive.